Tunnel Construction

Boring Video - Tunnel Construction Contractors

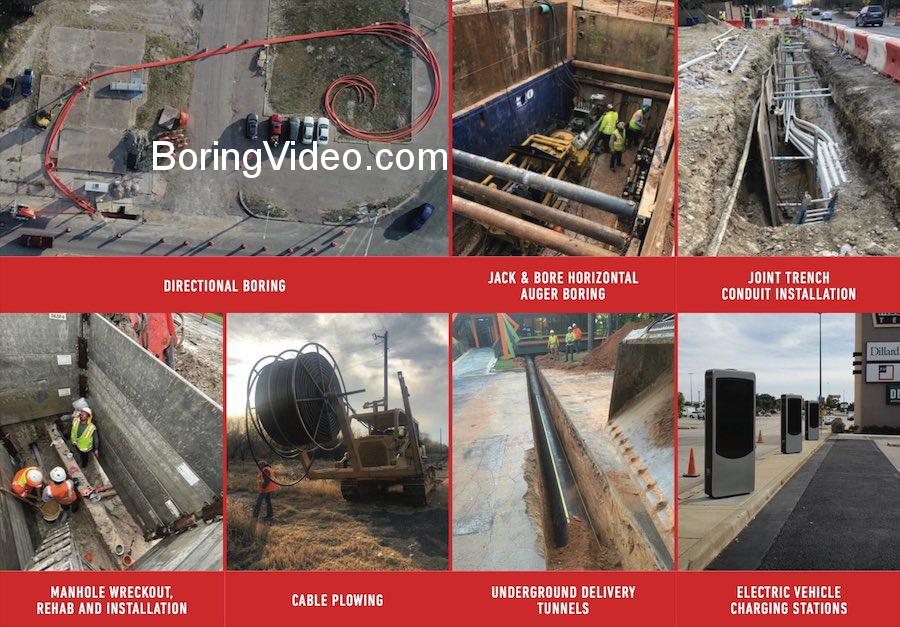

Tunnel construction in the jack and bore, horizontal auger boring, hand mining, and hand tunneling processes serves to create underground passages for various infrastructure projects. Below is a detailed breakdown of how these techniques are applied across industries like stormwater management, drainage, sewer systems, roads, railroads, and municipal works.

Boring Video - Tunnel Construction Companies

1. Jack and Bore (Auger Boring)

- Overview: A trenchless method where a horizontal casing pipe is installed underground without disturbing the surface. A rotating auger removes soil as the casing pipe is pushed forward.

- Applications:

- Stormwater & Drainage: Used to install large pipes for stormwater conveyance under roads or railways.

- Sewer: Common for placing gravity sewer lines, especially where minimal slope is needed.

- Roads & Railroads: Allows utility installations without surface disruption, ensuring minimal impact on traffic or rail operations.

- Municipal: Often used for water and gas pipelines beneath city streets.

2. Horizontal Auger Boring

- Overview: A mechanical boring process that uses a rotating auger inside a steel casing. It removes soil and rock while simultaneously advancing the casing pipe.

- Applications:

- Stormwater: Installs large conduits to handle runoff without open-cut excavation.

- Drainage & Sewer: Ideal for long runs of drainage or sewer pipes beneath obstacles like highways or buildings.

- Railroads: Effective for installing crossing pipes beneath rail tracks without disturbing train schedules.

- Municipal: Provides a cost-effective solution for utility installations under existing infrastructure.

3. Hand Mining

- Overview: A traditional method where workers manually excavate soil, supported by timber or steel braces, and install lining systems to prevent collapse.

- Applications:

- Sewer & Drainage: Used in confined spaces where precision is required, especially for smaller-diameter pipes.

- Stormwater: Hand mining is often chosen for access tunnels leading to larger stormwater systems.

- Roads & Railroads: Used in small, sensitive projects where mechanized methods might not be feasible.

- Municipal: Common in older cities with congested underground utilities or historical preservation concerns.

4. Hand Tunneling

- Overview: Similar to hand mining but specifically designed for creating larger tunnels. Excavation and support systems (like shotcrete or precast segments) are used to maintain stability.

- Applications:

- Stormwater & Drainage: Builds large underground stormwater retention or drainage systems in urban areas.

- Sewer: Allows installation of large-diameter sewer tunnels in urban environments.

- Roads & Railroads: Used to build access tunnels or utility corridors under existing infrastructure.

- Municipal: Supports larger infrastructure projects like utility relocation or tunnel expansion.

Stormwater & Drainage

- Purpose: Managing rainwater and preventing flooding.

- Role of Tunnel Construction:

- Creates underground channels to collect and transport water efficiently.

- Reduces surface-level disruption and ensures the sustainability of urban drainage systems.

Sewer Systems

- Purpose: Convey wastewater and sewage to treatment facilities.

- Role of Tunnel Construction:

- Installs pipelines with precision slopes to maintain flow.

- Avoids disrupting surface activity in densely populated areas.

Roads & Railroads

- Purpose: Maintain the integrity of transportation infrastructure while adding underground utilities.

- Role of Tunnel Construction:

- Enables the crossing of utilities like water, gas, and electricity under critical infrastructure.

- Reduces delays and ensures minimal disruption to commuters and freight services.

Municipal Projects

- Purpose: Support city infrastructure, including water, sewage, and utilities.

- Role of Tunnel Construction:

- Facilitates new utility installations and expansions without damaging roads or buildings.

- Ensures compliance with safety, environmental, and zoning regulations.

Advantages of Tunnel Construction

- Minimized Surface Disruption: Ideal for urban and high-traffic areas.

- Cost-Effective: Reduces the need for extensive open-cut excavation.

- Precision: Achieves exact gradients for gravity systems like sewer and drainage lines.

- Versatility: Applicable in various industries and soil conditions.

Boring Video - Tunnel Construction Near Me

Each technique’s application depends on project scale, soil conditions, and environmental factors. Together, these methods form the backbone of modern underground construction for critical infrastructure.