Pilot Tube Auger Boring

Boring Video - Pilot Tube Auger Boring Contractors

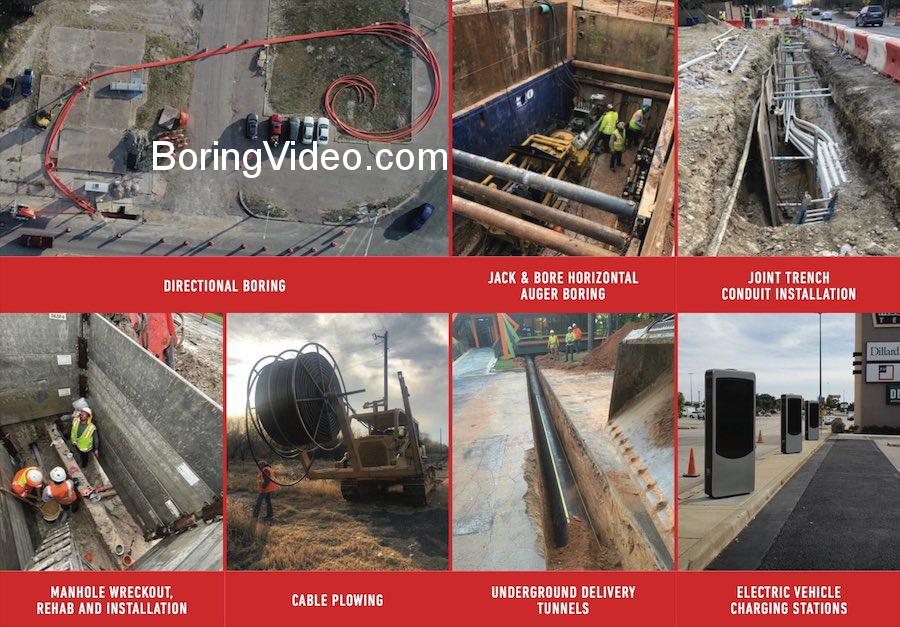

Pilot Tube Auger Boring (PTAB) is a trenchless construction method used for highly accurate pipeline installations, especially in applications requiring precise on-line and on-grade alignment. Below is an explanation of how PTAB integrates into various industries and applications like jack and bore, horizontal auger boring, oil & gas, sewer, drainage, and municipal projects.

Boring Video - Pilot Tube Auger Boring Companies

What is Pilot Tube Auger Boring?

PTAB is a hybrid trenchless technology that combines elements of pilot tube steering, horizontal auger boring, and microtunneling. It is particularly effective for small-diameter pipelines (commonly 4 to 24 inches) requiring high accuracy and controlled installations.

The process involves three key stages:

- Pilot Tube Installation: A guided pilot tube with an optical guidance system is advanced, ensuring alignment and grade.

- Reaming/Enlargement: A reamer or cutter head enlarges the bore to the desired diameter.

- Pipe Installation: The product pipe (e.g., steel, PVC, or concrete) is jacked into place, following the pilot tube path.

Applications Across Industries

1. Jack and Bore

- PTAB is often considered a precision-focused evolution of traditional jack and bore.

- It is used where jack and bore lacks the required grade accuracy, as PTAB allows precise alignment and control.

- Ideal for gravity sewers or other systems where % fall must meet design tolerances.

2. Horizontal Auger Boring

- PTAB complements horizontal auger boring in areas needing enhanced accuracy.

- It combines the robustness of auger boring with the precision of pilot tube guidance for small-diameter, grade-critical installations.

3. Trenchless Technology

- PTAB is a core trenchless method due to its minimal surface disruption.

- It’s especially valued in urban or environmentally sensitive areas where open-trench excavation is not feasible.

4. Oil & Gas

- In oil and gas, PTAB is used to install conduits for pipelines crossing under roads, railroads, or other obstacles.

- While limited to smaller diameters, it ensures precise alignment, critical for avoiding conflicts with existing utilities.

5. Sewer, Drainage, and Stormwater

- PTAB excels in installing gravity-flow systems where on-grade precision (e.g., a 0.5% fall) is mandatory.

- The method avoids costly post-installation adjustments by ensuring the pipeline aligns with design specifications from the start.

6. On-Line and On-Grade

- PTAB’s optical guidance system ensures installations are precisely on-line (horizontal alignment) and on-grade (vertical slope).

- Essential for municipal and gravity-driven systems like wastewater and stormwater pipelines.

7. Roads and Railroads

- PTAB is widely used for crossings under roads and railroads, where traditional excavation would disrupt traffic or rail operations.

- Compliance with strict engineering tolerances is critical to avoiding settlement issues in these areas.

8. Municipal and Government Projects

- PTAB is frequently specified in municipal projects due to its precision, cost-effectiveness, and low environmental impact.

- It’s a preferred method for installing utility pipelines in densely populated or regulated areas.

Advantages of PTAB

- High Precision: Achieves grade and alignment tolerances as low as ±0.1%.

- Cost Efficiency: Minimizes risks of over-excavation or misalignment.

- Minimal Disruption: Ideal for urban or sensitive environments.

- Versatility: Suitable for various soil types and pipeline materials.

Boring Video - Pilot Tube Auger Boring Near Me

Key Challenges

- Limited to smaller diameters (compared to larger HDD or auger boring applications).

- May require skilled operators and advanced equipment, increasing initial investment.

In summary, PTAB is a critical innovation for trenchless projects requiring precision and reliability. It integrates seamlessly into jack and bore, horizontal auger boring, and a variety of industries, particularly in applications requiring on-line and on-grade accuracy.